The Importance of Trench Safety: Safeguarding Lives and Enhancing Construction Practices

Trench safety is a critical aspect of construction and excavation activities that warrants significant attention. Within the depths of narrow and deep excavations, workers face inherent risks that necessitate strict adherence to safety protocols. In this article, we delve into the paramount importance of trench safety and explore essential measures for safeguarding lives below the surface, ultimately improving construction practices.

Understanding the Significance:

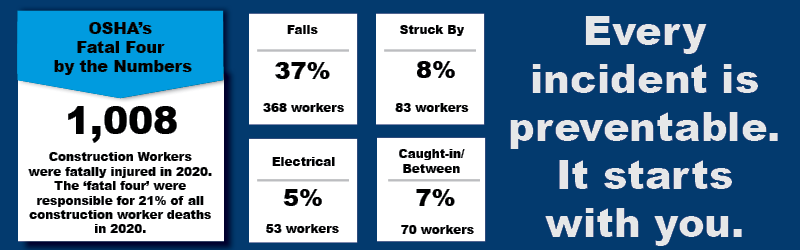

Comprehending the risks associated with trenching and excavation work is crucial. These activities pose a range of hazards, including cave-ins, falls, engulfment, hazardous atmospheres, and falling objects. Among these risks, trench collapses pose a particularly grave threat, burying workers under massive volumes of soil, resulting in severe injuries or fatalities. Therefore, prioritizing trench safety becomes indispensable in preventing accidents and ensuring the well-being of those involved in excavation work.

Key Safety Measures:

- Implementing Protective Systems: Employing effective protective systems forms the cornerstone of trench safety. Trench boxes, or trench shields, provide structural support to prevent soil collapse. Shoring techniques, such as hydraulic shoring and timber shoring, reinforce trench walls, mitigating the risk of collapses. Similarly, employing sloping and benching techniques involves cutting back trench walls at specific angles to minimize cave-in hazards.

- Competence and Training: The competence and training of personnel engaged in trenching and excavation work are of paramount importance. Comprehensive training programs equip workers with the ability to identify potential hazards, comprehend soil types, utilize protective systems, and operate equipment safely. Regular safety briefings and refresher courses reinforce adherence to safety protocols and best practices.

- Site Evaluation and Planning: Thorough site evaluations are essential before commencing any trenching operation. This evaluation includes identifying existing utilities, assessing soil composition, evaluating water accumulation risks, and identifying potential hazardous atmospheres. Detailed planning ensures the implementation of appropriate safety measures and the availability of necessary equipment on-site.

- Ensuring Adequate Access and Egress: Establishing safe entry and exit points in trenches is crucial. Constructing properly designed ladders, stairways, or ramps enables workers to enter and exit trenches safely. Minimizing the distance between access points ensures swift evacuation during emergencies.

- Atmospheric Monitoring: Regularly monitoring atmospheric conditions within trenches is imperative to prevent exposure to hazardous gases and oxygen depletion. Thorough monitoring for toxic gases like methane or hydrogen sulfide ensures a safe working environment. Installing effective ventilation systems guarantees a continuous supply of fresh air.

- Personal Protective Equipment (PPE): Providing adequate personal protective equipment to workers engaged in trenching operations is crucial. This includes hard hats, high-visibility clothing, safety boots, and protective gloves. Workers should also utilize respiratory protection when at risk of inhaling hazardous substances.

Trench Safety Tools & Resources from OSHA & MOCGA:

OSHA Resources:

- Trenching and Excavation Safety and Health Topics page

- Trenching and Excavation Safety, OSHA Pub #2226

- OSHA Fact Sheet – Trenching and Excavation Safety (English, Spanish)

- Trench Safety QuickCard (English, Spanish)

- Trench Collapses Can Be Deadly: OSHA Alert (English, Spanish)

- Trenching Poster (English, Spanish)

- Trenching Safety Poster: 5 Things You Should Know to Stay Safe

MOCGA Outreach Materials:

- MO CGA 11×17 Posters

- MOCGA Pre-Excavation Safety Checklist

- MOCGA Toolbox Talk – Buried Utility Safety

- MOCGA Toolbox Talk – Trench Safety

- Trenching and Excavation Safety Inspection Checklist

Final Thoughts:

Ensuring trench safety is a shared responsibility among employers, supervisors, and workers alike. By recognizing potential risks and implementing robust safety measures, accidents can be minimized, and the well-being of those working below the surface can be safeguarded. Trench safety must never be compromised, and adherence to best practices, comprehensive training, and the use of protective systems are indispensable in protecting lives and preventing tragedies in the construction and excavation industry. Let us prioritize trench safety as an integral part of every trenching operation, enhancing construction practices and fostering a secure working environment.