Ensuring a Safe and Joyous Christmas: Essential Tips for a Secure Celebration

Ensuring a Safe and Joyous Christmas: Essential Tips for a Secure Celebration

Ensuring safety extends beyond the workplace, especially during the festive season like Christmas. While workplace safety is crucial, it’s equally important to prioritize the well-being of employees and their families at home. Incorporating safety measures into holiday celebrations not only safeguards individuals in the workplace but also extends to creating a secure environment at home. From responsibly decorating homes to preventing fire hazards, fostering a culture of safety ensures that the joy of Christmas is complemented by a commitment to the well-being of both employees and their families.

Download Printable Christmas Safety Tips

Christmas Safety Tips – Preparing Yourself

The holiday season brings with it a magical ambiance, but it’s crucial to prioritize safety to guarantee a joyful and accident-free Christmas. In this article, we’ll explore five key safety tips to keep in mind during the festive season.

Decorative Lights Safety: Illuminate Safely

As you adorn your home with twinkling lights, prioritize safety by inspecting each strand for frayed wires or damaged sockets. Ensure that outdoor lights are approved for exterior use and keep them away from flammable materials. Turn off decorative lights before bedtime to prevent any potential electrical hazards.

Candle Safety: Glow Responsibly

Candles add warmth to the holiday atmosphere, but they also pose a fire risk. Opt for flameless LED candles for a safer alternative. If you choose traditional candles, never leave them unattended and keep them away from combustible materials. Consider using candle holders with sturdy bases to prevent tipping.

Pet and Child Safety from Poinsettias, Holly & Mistletoe: Know Your Flora

While these festive plants contribute to the holiday cheer, they can be harmful to pets and children if ingested. Keep poinsettias, holly, and mistletoe out of reach, and consider artificial alternatives to ensure a hazard-free environment for your furry friends and little ones.

Fire Safety: Preventing Unwanted Surprises

Be mindful of fire safety by keeping flammable items, such as wrapping paper, away from open flames or space heaters. Test smoke alarms to ensure they are in working order, and establish a designated safe area for disposing of ashes from fireplaces. It’s better to be proactive and prevent fire-related incidents.

Ladder Safety: Reach New Heights Safely

Decorating often involves reaching high places, but ladder-related accidents are common during the holidays. Choose a sturdy ladder and place it on a level surface. Have someone assist you, and never overreach or stand on the top rungs. Taking precautions with ladder safety is key to preventing falls and injuries.

Things to Remember

By incorporating these Christmas safety tips into your holiday preparations, you can create a festive and secure environment for your loved ones. Prioritizing safety ensures that the joy of the season is accompanied by peace of mind, allowing you to celebrate Christmas with the utmost cheer and well-being.

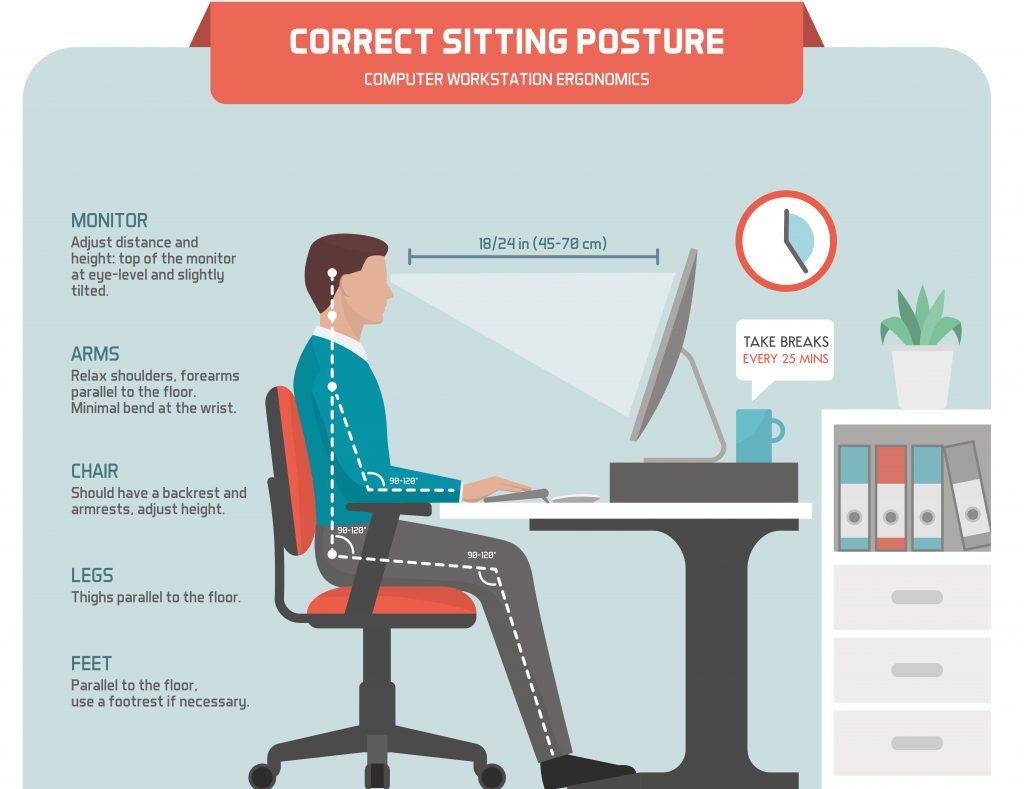

Why Desk Ergonomics?

Why Desk Ergonomics? Celebrating Thanksgiving Safely for a Joyful Gathering

Celebrating Thanksgiving Safely for a Joyful Gathering

DOL Proposed Rule Changes Regarding Authorized Employee Representation During Workplace Inspections

DOL Proposed Rule Changes Regarding Authorized Employee Representation During Workplace Inspections