An Easy Ergonomics Guide for Employers

An Easy Ergonomics Guide for Employers

Welcome to our latest deep-dive look at an important workplace resource entitled “Easy Ergonomics: A Practical Approach for Improving the Workplace.”

In today’s fast-paced work environment, prioritizing employee well-being and productivity is essential. This comprehensive guide promises to make workplace ergonomics accessible and effective for businesses of all sizes. Let’s dive into the key features that make this publication a must-have for anyone invested in creating a safer and more comfortable work environment.

The Importance of Ergonomics in the Workplace

In the modern professional landscape, where individuals spend a significant portion of their day at desks and workstations, understanding and implementing ergonomic principles is crucial. “Easy Ergonomics” begins by highlighting the importance of creating a workspace that promotes health, productivity, and overall job satisfaction. This section serves as a compelling reminder of why prioritizing ergonomics is a smart investment for both employers and employees.

Practical Solutions for Common Workplace Challenges

One of the standout features of this valuable resource is its hands-on approach to problem-solving. The publication provides practical solutions to common workplace challenges, such as uncomfortable seating arrangements, poorly designed workstations, and improper computer setups. Each solution is presented in a clear and actionable format, making it easy for readers to implement positive changes immediately.

User-Friendly Tips and Tricks

Navigating the intricacies of workplace ergonomics can be overwhelming. Moreover, this guide breaks down complex concepts into user-friendly tips and tricks. From proper desk chair adjustments to the optimal placement of computer monitors, readers will appreciate the simplicity and effectiveness of the actionable advice provided in this section.

Real-life Case Studies

To further illustrate the impact of ergonomic improvements, “Easy Ergonomics” incorporates real-life case studies. These stories showcase how organizations successfully transformed their workplaces, resulting in improved employee satisfaction, reduced absenteeism, and increased productivity. The inclusion of tangible examples adds a layer of authenticity to the guide, making it relatable and inspiring for readers.

Things to Remember

Remember that “Easy Ergonomics: A Practical Approach for Improving the Workplace” stands out as a valuable resource for anyone looking to enhance workplace safety and comfort. Its accessible language, practical solutions, and real-life examples make it a must-read for employers, HR professionals, and individuals interested in fostering a healthier and more productive work environment. Invest in the well-being of your team and elevate your workplace with the insights

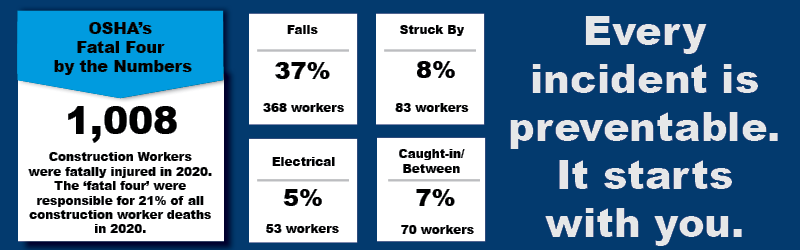

Musculoskeletal Disorders and Workplace Factors

Musculoskeletal Disorders and Workplace Factors

Ergonomic Guidelines for Shipyards (OSHA)

Ergonomic Guidelines for Shipyards (OSHA)